We are a turnkey contract manufacturer of precision machined parts

As our partner, you can be confident that your parts will arrive on-time and complete to print.

As our partner, you can be confident that your parts will arrive on-time and complete to print.

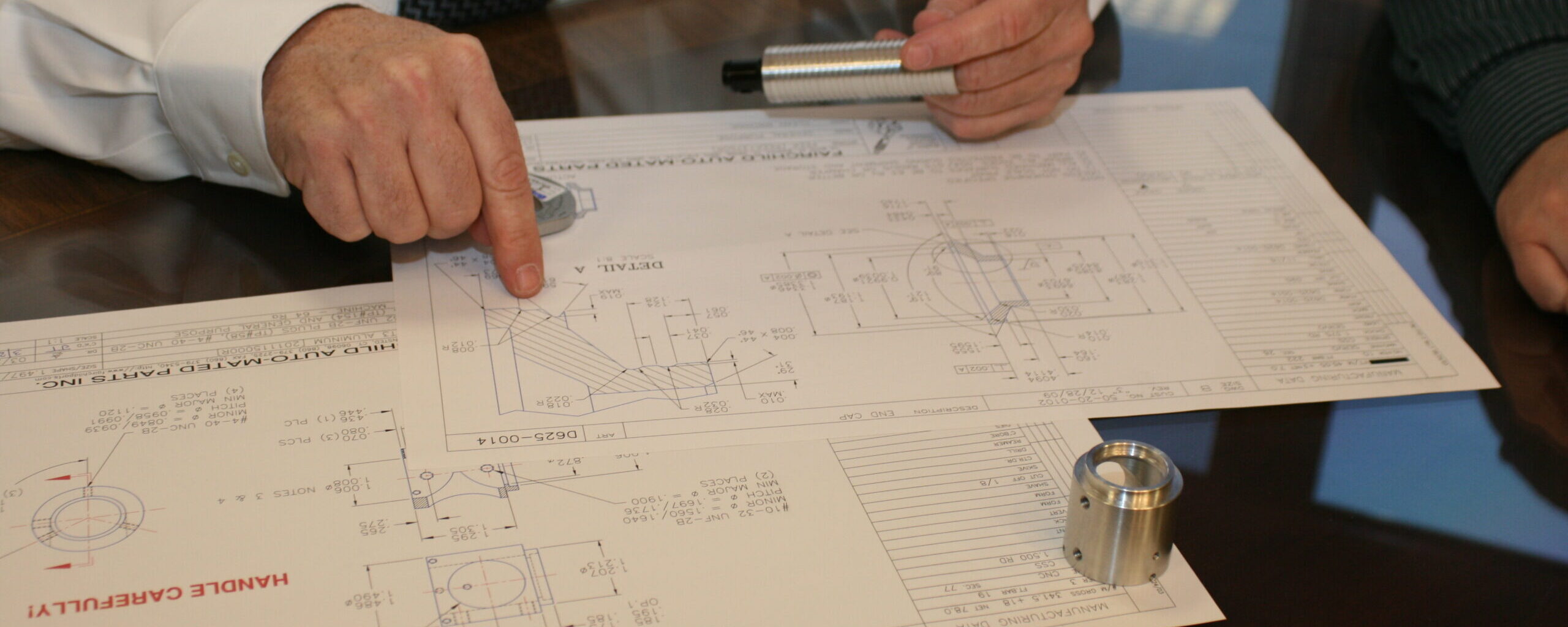

Our engineering experts use your drawing specifications to develop an optimized manufacturing process. During its development, we assess the process for manufacturability, cost reduction opportunities and potential risks. We’ll quote your part with the best manufacturing process and if there’s any opportunities, we’ll raise the question with the goal of saving you time and money.

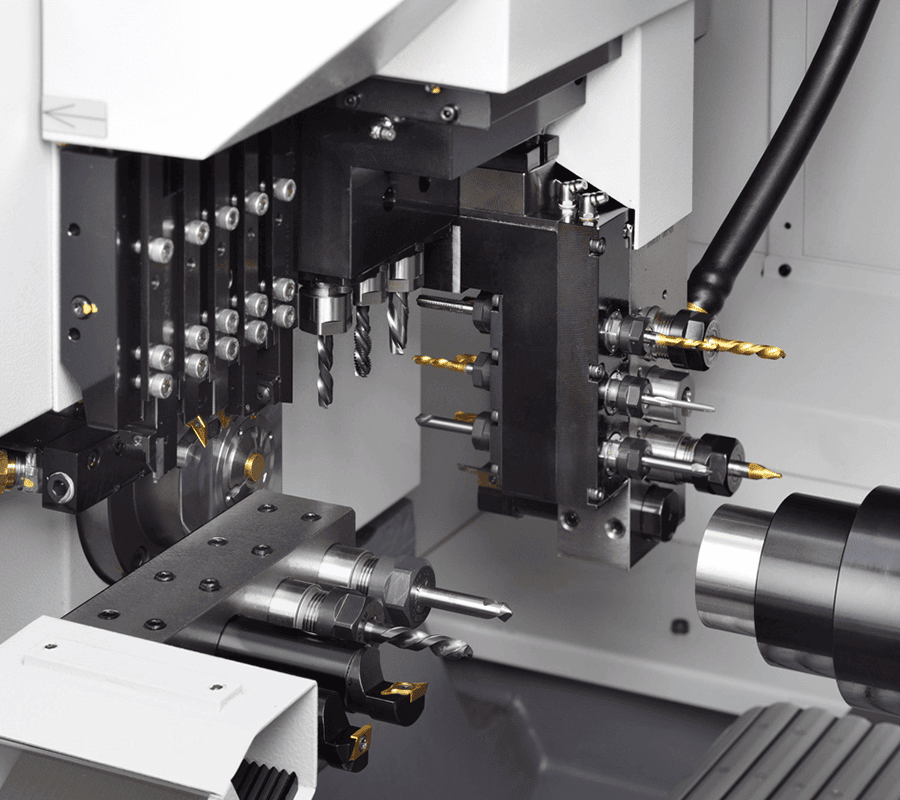

Our Swiss CNC turning machines can be used to produce all types of complex components, from connectors to fasteners, fittings, and screws. It is our commitment to owning only the most advanced technology that allows us to manufacture precision machined parts at competitive prices. Fairchild possesses seven-axis CNC Swiss turning machinery equipped with magazine auto bar feeders that can maintain an ultra-tight tolerance of just (+/-) 0.0001 of an inch.

From boring and deburring to broaching, deep-hole drilling, and threading, we have successfully assisted a wide range of industries from medical to aerospace and marine defense. We can operate on a wide variety of parts in a broad array of sizes, shapes, and materials measuring up to 1.25 inches in diameter

Our shop is well-equipped with top-of-the line CNC turning and milling machinery capable of holding ultra-precision tolerances down to (±) 0.0001 of an inch. Our five-axis CNC turning machinery possesses magazine auto bar feeders and can manufacture parts measuring up to 2 inches in diameter. We can also chuck individual work pieces measuring up to 6 inches in diameter.

In addition, our high-speed, live tooled four-axis vertical machining center comes equipped with a large work envelope and turn-table stock changers. Our VMC can perform both contour milling and profiling operations, offering a repeatability of just (+/-) .0001 of an inch. Even on the most complex parts, our advanced milling equipment can machine reamed or tapped holes at precise locations.

With our top-notch custom assembly operations, Fairchild Auto-Mated Parts offers comprehensive services at competitive prices that have successfully served the needs of multiple industries, ranging from aerospace to consumer goods. While we focus on box-build/bench top custom assembly, we also specialize in electro-mechanical assemblies for the aerospace industry.

We have spent years selecting and vetting vendors to provide the specialized services your parts need. Our network of approved vendors provide services including but not limited to plating, heat treating, grinding, laser marking, brazing, testing and particle inspection. We collaborate closely with these partners to ensure the specifications are met and lead times are minimized.

We’ve machined parts for industries including aerospace, defense, musical instruments, oil exploration, electrical hardware, HVAC systems, and high-end measuring devices. We are always willing to take on new orders for any industry, ensuring we fully understanding the specifications and are confident in our ability to deliver a quality part.

Fairchild manufactures this delicate part from an aluminum extrusion supplied by customer. Special features include a .0005″ tolerance bore that receives a precision high speed bearing. The part is used in a high speed hand piece used by jewelers and dental technicians.

This two-piece assembly was designed by Fairchild’s engineers as part of a cost reduction program that resulted in saving a customers over $45,000 annually. Fairchild makes both parts and then assembles them, providing a part that is ready for insertion into the valve body used in in HVAC control system.

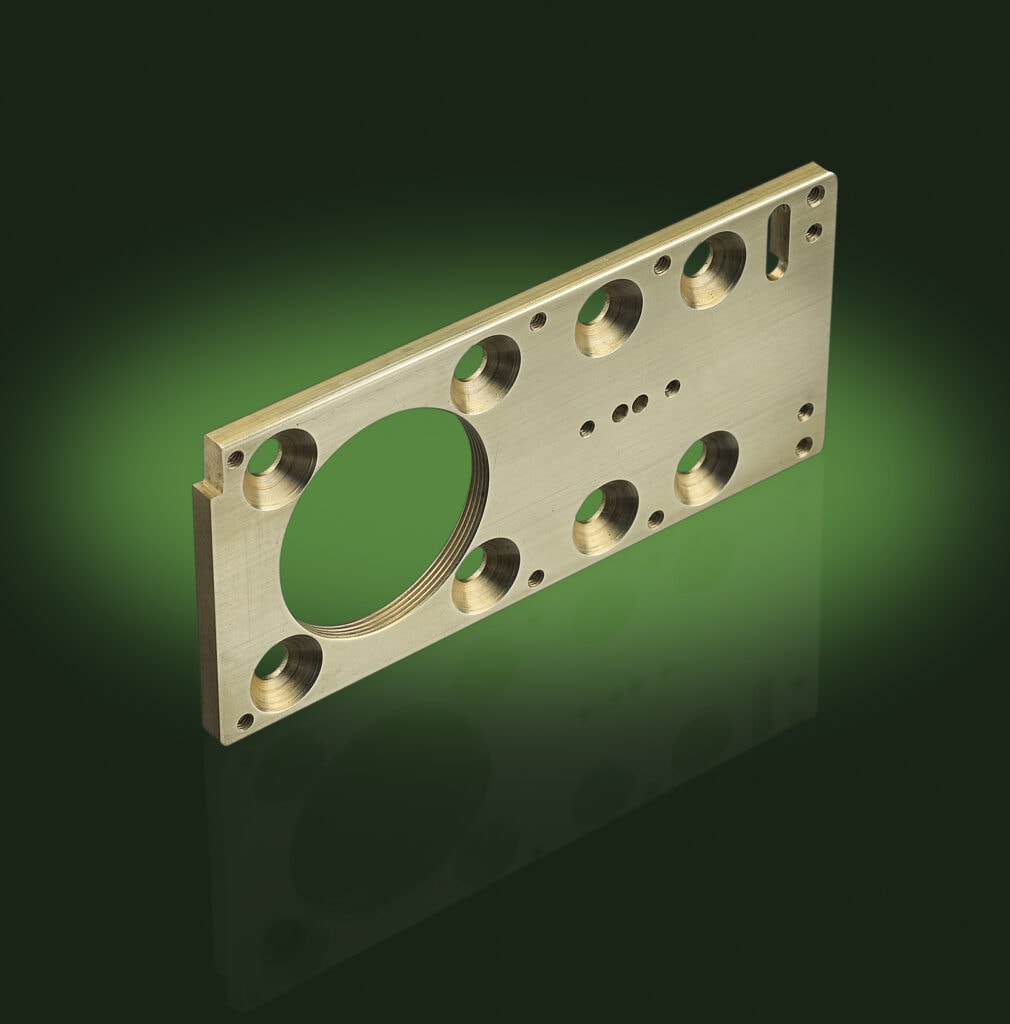

This part is an example of “flat work” machining performed on Fairchild’s high speed vertical machining centers.

Example of a two-piece welded assembly used in aerospace maintenance equipment.

Brass valve piston with added O-ring assembled and packaged and shipped complete to our customer.

This two-piece air nozzle assembly is used to direct inert gas during the repair and de-soldering of printed circuit boards components.

This part is made from 303 stainless steel. The part is then annealed and electro polished to accentuate its appearance.

This part is made from CDA 330 brass tubing. It is part of a communications phone handset used on naval vessels.

Fairchild can produce small parts as well. These components are threaded with #00-120 threads and are produced in lot sizes of up to 75,000 pieces per run!

Special three-piece assembly of an adjusting mechanism for a large radio telescope.